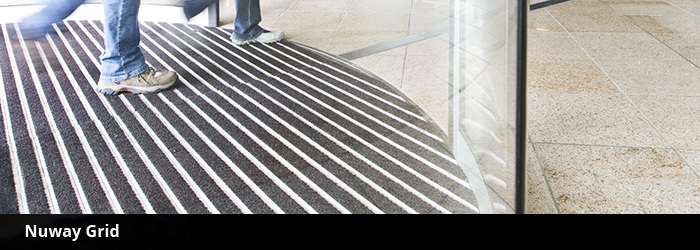

Every grid mat features 100% recycled, extruded aluminium interlocking carrier sections for durability, with infill strips joined together by rubber double connecting strips. The aluminium sections have a low-lustre anodised finish to comply with DDA requirements. Grid is constructed to spread heavy loads and to offer long lasting effective performance in demanding locations.

The carrier sections can be coupled with infill materials providing maximum design flexibility, allowing beautifully colour co-ordinated entrance areas to be created with primary and secondary entrance matting products that are perfectly matched. These materials include strips of textile infill in 13 different colourways drawn from the Coral classic, brush activ and burford ranges. Other textile inserts from the Coral range are available to special order. Rubber inlays are also available, which allow grid mats to be used outside.

Choose your insert - exterior use

Rubber

Rubber - for exterior and interior use.

Ultragrip

Ultragrip Rubber - for sure footing in multi directional entrances. For interior and exterior use.

Choose your insert - interior use.

Nuway Grid presents an ideal solution for entrance areas subject to high levels of pedestrian traffic and where the soiling expected has a high moisture or dust content. When supplied with optional rubber inserts,Grid also becomes suitable for external entrances. Every Grid mat comprises a series of low lustre interlocking aluminium carriers with infill strips joined together by rubber double connecting strips. No nuts or screws are required.

Additional Information

Infills: Extensive choice of standard inserts includes a selection of 13 different textile inserts from the Coral classic, brush active and burford ranges and rubber inserts.

Carrier Section: Low Lustre anodised finish complies with DDA requirements. Patented crimping action firmly secures textile or rubber insert within the carrier section.

Cleaning & Maintenance

The role of an entrance flooring system British Standard 7953 Part 5.1

"The entrance flooring system should scrape, wipe and retain soil, making contact with both feet of people entering the building and, in the case of wheeled traffic, with the circumference of the wheels"

British Standard 7953: 1999 states that EFS is necessary in order to:

- Reduce the risk of slip injuries

- Prolong the life of the interior floor finish

- Reduce the cost of ongoing maintenance